LED Lighting Solutiong

With many years of experience, Sunlite provides customized LED lighting solutions based on customer needs for interior LED products. These products can be customized in terms of color temperature, size, length, light source, power, etc. Please contact us for more information!

|

Custom Options:

1.Product types: LED strip light, LED tape, LED module

2. Custom parameters:

- Lamp beads(SMD2835、SMD5050、SMD5630, etc.)

- Color(White, pure white, warm white, cool white, red, green, blue, yellow, cool blue, rose red, etc.)

- Color temperature(2400K-15000K)

- Color Rendering Index (CRI)

- Power

- Luminous effect and lamp bead arrangement (Sunlite can provide design services)

|

Custom capacity:

01

Personnel and Experience

1.We have an R & D team with more than 10 years of experience in the LED industry. They are well equipped to meet the reasonable needs of customers. Whether it is commercial lighting or decorative lighting, we can give customers the most reasonable solution.

2.We have good hardware facilities outfitted with EVERFINE high accuracy power supplies, spectrometers, integrating spheres, illuminance meters, constant temperature testers, optical microscopes, and another measurement instruments. We can fully meet the testing requirements of our products to ensure high quality.

3.We have an efficient management team and a young, dynamic, and creative staff. They provide customers with high-quality pre-sales and after-sales service.

02

Raw material

- Various brands of LED lamp beads including SMD2835, SMD 5050, SAMSUNG 5630, OSRAM and CREE, etc.

- Independent R&D of large-angle optical lens, including 160 ° and 170 ° diffuse reflection lens.

- Fire and UV protection of ABS and PVC materials.

- High quality 1.6mm and 2.0mm Aluminum PCB board.

|

Processing capacity:

Equipment:

1.Vertical injection molding machine

2.UV curing machine

3.High accuracy array spectroradiometer

4.High-speed welding machine

5.JUKI placement machine

6.Handheld spectrometer

|

Production process:

LED placement → Reflow soldering → Visual inspection → Quality Testing → Wire bonding → PCB Depaneling → Quality Testing → Assembly lens → Injection Molding → Aging Testing → Performance Testing (bad repair) → Tape pasting and Packaging

|

Testing:

- Electrician instrument: dynamometer, digital multimeter

- Thermal instrumentation: thermometer, etc.

- Special instrumentation: electrical resistance tester

- Measuring tool: microscope, force gauge, etc.

- Environmental testing equipment: constant temperature and humidity test chamber, etc.

- Energy efficiency testing equipment: integrated analysis system

1. Visual inspection standards

The surface of the product is spotless with no residual flux on the pad. The solder joint is clean. There is no missing solder, short circuit, and soldering offset.

2. Electrical inspection standards

When powering up the LED lights, our inspectors check for LED spots that do not light up and conduct a high temperature test, water-proof test, and for electrical failure.

|

Custom case one:

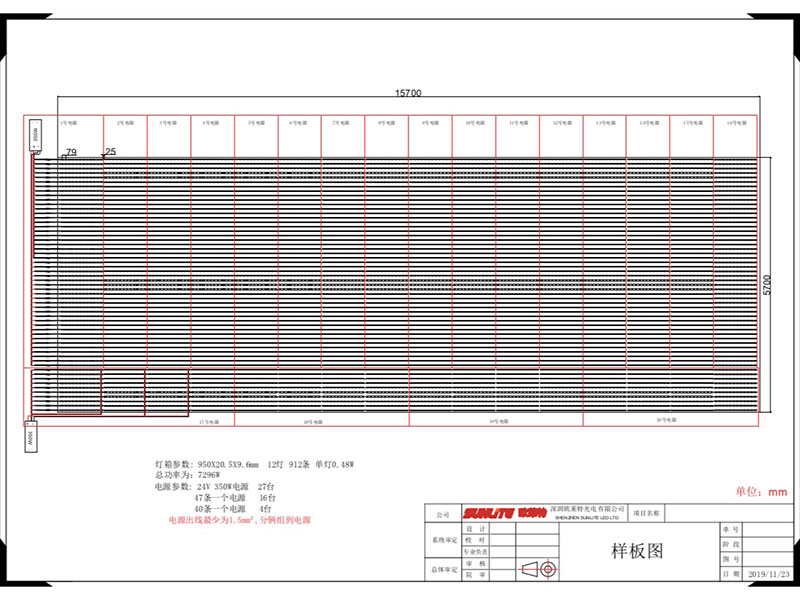

Custom requirements: they need LED light boxes which are used as TV backlights in subway stations. The dimensions of the LED light box should be 3m(length) × 1.5m(width) × 0.12m(thickness). The power of the whole LED light box should be less than 100W. Its brightness should be more than 2800 Lux and evenness should be more than 90%. The customer tried the products of several manufacturers but their products did not meet their requirements. (see picture 1)

Solution: We reduce the number of light bars and increase the span of the LED so as to ensure the light box is receiving light evenly. We calculate the power of each LED according to the designated total power and then test whether the light box can reach the standards of the customer.

We customized an LED light box for the customer which was made up of diffused LED light bars. The length of the LED light bar is 1.44m and it is designed with 12 LEDs. The span between the LEDs is 12cm. The power of each LED is 0.7W and the total power of the light box is 100.8W. Consider the voltage drop the actual total power is 98W (see picture 1). The customer was very satisfied with our solution.

|

Custom case two:

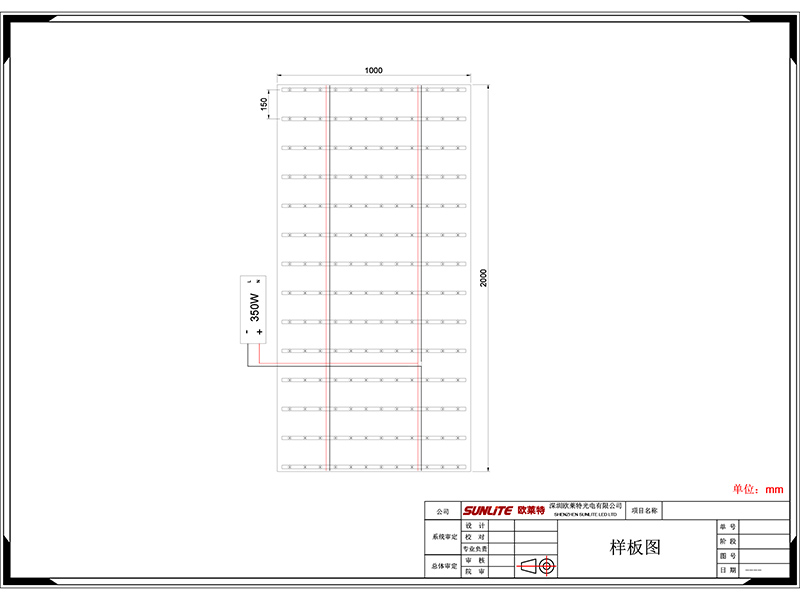

Custom requirements: They needed a double-sided light box of 1.6m(length) × 1.2m(width) ×0.06-0.08m (thickness). It should adopt side lighting and its brightness should be more than 3000 Lux, and its light should be even. There should be no dark zones or yellow spots on the surface of the light box.

Solution: We used a DLW45E and DLW446E light box which are equipped with OSRAM 3030 LEDs. The specification of DLW45E is 5LEDs/0.25m and 11W/PC and the specification of DLW446E is 10LEDs/0.5m and 22W/PC. Their pins adopt seamless connection. This light box is equipped with a special lens and adopts side lighting which features evenness of lighting and without yellow spots. The light box met all of the the customer’s requirements while its thickness is only 6cm.