Choosing the right profile for your aluminum LED strip is very important. It affects how well they work and how they look. For example, materials like aluminum help get rid of heat. This keeps the temperatures lower. Good heat management is necessary. If heat is not managed well, LED parts can wear out faster. So, you need to think about how your choice impacts the life and brightness of your aluminum LED strip lights. In the end, you might ask: which profile is best for aluminum LED strips?

Key Takeaways

Aluminum profiles are great at managing heat. This helps LED strips last longer and work better.

Plastic profiles are lighter and cheaper. However, they might not handle outdoor conditions or heat well.

Aluminum profiles are more durable. They protect against dust and moisture, making them good for many places.

Think about how aluminum profiles look. They can improve modern decor. Plastic profiles let you be creative with designs.

Look at long-term costs. Aluminum profiles might cost more at first. But they can save money on replacements and upkeep later.

Durability

Aluminum Profile Durability

Aluminum profiles are much stronger than plastic profiles. They can handle stress and do not easily change shape. This makes them great for many uses. The strong nature of aluminum keeps your LED strips safe from hits and outside conditions.

Lifespan: LED strip lights usually last between 25,000 to 50,000 hours. This means they can work for about 8 to 17 years if used daily. Better quality COB LED strip lights can last up to 100,000 hours, which is almost 34 years with normal use. This long life is partly because aluminum profiles manage heat well.

Heat Management: Aluminum profiles get rid of heat from LED strips very well. This stops overheating, which can hurt performance and shorten life. Good cooling lowers heat stress on LED strips, making them last much longer.

Protection: Aluminum profiles protect LED strips from dust, water, and damage. This protection is very important in places with changing humidity and temperature. It helps keep your lights working well and looking good over time.

Plastic Profile Durability

Plastic profiles are lighter and often cheaper, but they are not as strong as aluminum. They can be affected by outside conditions that can weaken them.

UV Exposure: Long exposure to UV light can change the surface of plastic profiles. For example, polystyrene (PS) shows big surface changes, while polypropylene (PP) has surface changes and forms carbonyl species after being exposed for a long time.

Chemical Interactions: Different plastics react in different ways to outside conditions. For instance, polycarbonate (PC) changes its chemical bonds, while polyethylene (PE) changes due to environmental exposure. These changes can make the profile weaker over time, leading to possible failures.

Plastic Type | Effect of UV Exposure | Chemical Changes Observed |

|---|---|---|

PS | Altered surface | Decrease in C 1 s(C‒H) → 1 πC=C* peak, indicating bond breakage |

PC | Higher intensity of C1s(C = O) peak | Increased absorption at 289.2 eV, indicating new chemical bonds |

PP | Surface changes noted | Formation of carbonyl species after prolonged exposure |

PET | No significant alteration | N/A |

PE | Different alteration from environmental exposure | N/A |

Heat Dissipation

Aluminum Heat Dissipation

Aluminum profiles are great at getting rid of heat. They work like good heat sinks. Their thermal conductivity is 237 W/mK. This is much better than plastic profiles, which only reach 0.2 W/mK. Because of this, aluminum pulls heat away from the LEDs very well. This means your aluminum LED strips will run cooler.

Benefits of Aluminum Heat Management:

Aluminum profiles keep LED temperatures low.

They handle extra heat and stop overheating.

This strong heat control is helpful in busy places, making your LEDs last longer.

Studies show that an LED’s life depends on its temperature. If heat is not controlled well, the LEDs can lose performance and not last as long. So, using aluminum profiles can help you avoid heat problems. This way, your LED strips will last longer and work better.

Plastic Heat Dissipation

Plastic profiles are lighter and cheaper, but they do not handle heat well. Their lower thermal conductivity means they cannot cool down as well as aluminum. This can cause some problems:

Consequences of Poor Heat Management:

Overheating can happen, which shortens the life of the LEDs.

Bad heat dissipation in plastic profiles can cause big performance issues, as shown in many studies of LED technology.

While there are not many specific cases of LED failure from heat issues in plastic profiles, most experts agree that heat management is very important for LED performance. So, if you pick plastic profiles, be careful about the risks of heat buildup.

Aesthetics

Aluminum Aesthetics

Aluminum profiles look really good. They have a smooth and modern style that many designers like. You can find finishes like satin anodized aluminum and powder-coated black or white. These finishes make the profiles look better and last longer. Aluminum profiles fit well with different interior designs. This is why they are popular in modern spaces.

Designers usually think aluminum profiles look better than plastic ones. You can customize the finishes, which helps them match modern decor. Whether you want a simple look or an industrial feel, aluminum profiles can meet your style needs.

Plastic Aesthetics

Plastic profiles have their own unique looks that can fit certain design goals. They let light pass through, which creates a soft and warm glow. This makes plastic profiles great for places where gentle lighting is needed. Also, plastic profiles are more flexible, so they can be shaped into creative designs.

While plastic may not look as sleek as aluminum, it has its own charm. You can find plastic profiles in many colors and styles, which allows for fun and creative designs. This flexibility is especially nice for places like kids’ rooms or themed areas.

Cost Analysis

When you pick between aluminum and plastic profiles for your LED strips, cost is very important. Knowing how much each option costs helps you make smart choices for your projects.

Aluminum Cost Factors

Aluminum profiles usually cost more at first than plastic ones. But, they last longer and manage heat better, which can save you money later. Here’s a look at the average prices:

Profile Type | Price per Foot |

|---|---|

Basic Aluminum Profiles | $3 – $5 |

Intermediate Aluminum Profiles | $6 – $12 |

Premium Architectural Profiles | $15 – $25 |

Plastic Profiles | N/A |

Even though aluminum profiles might seem pricey at first, their long life and good performance can make them worth it. You will likely need fewer replacements and spend less on maintenance over time.

Plastic Cost Factors

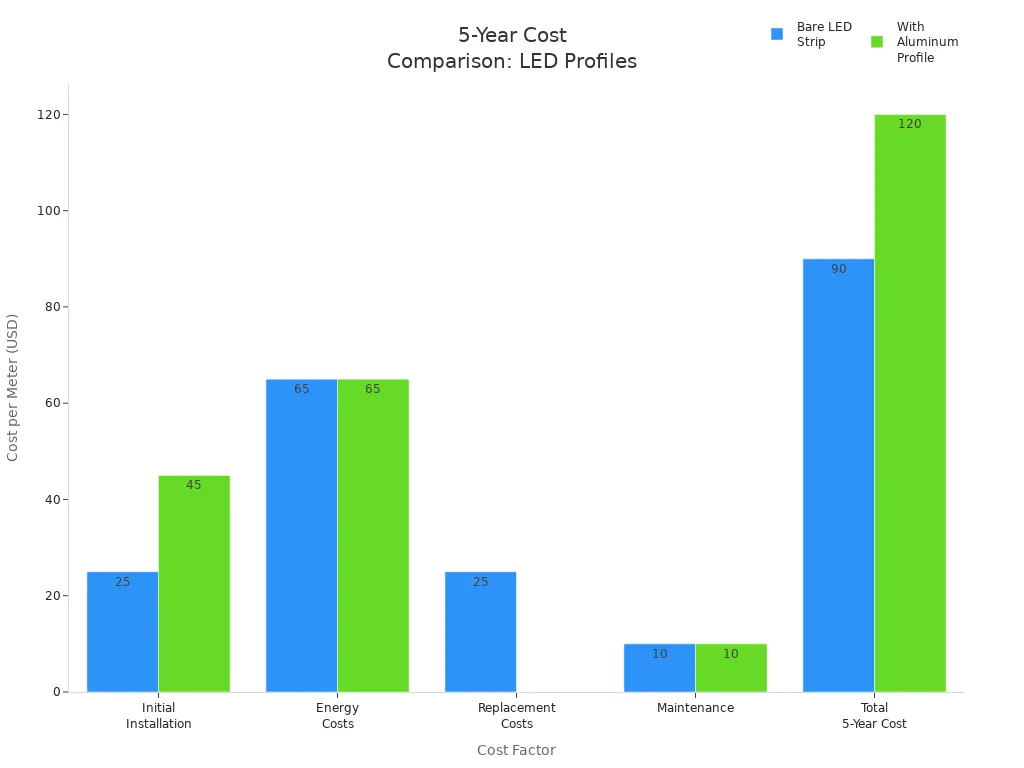

Plastic profiles are usually cheaper to buy at first. However, they are not as strong and do not cool down as well, which can lead to higher costs later. For example, look at these costs over five years:

Cost Factor | Bare LED Strip | With Aluminum Profile | 5-Year Total |

|---|---|---|---|

Initial Installation | $25/m | $45/m | $45/m |

Energy Costs | $15/m/year | $13/m/year | $65/m |

Replacement Costs | $25/m (Year 3) | $0 | $0 |

Maintenance | $5/m/year | $2/m/year | $10/m |

Total 5-Year Cost | $90/m | $120/m | $120/m |

Best Applications

Applications for Aluminum LED Strips

Aluminum profiles are great for many commercial and industrial places. They are light, strong, and resist rust. This helps them cool down and protect LED strips well. You will see aluminum profiles used in:

Retail Stores: They help LED strips last longer and handle tough conditions.

Restaurants and Eateries: Their modern look fits well with stylish decor and gives good lighting.

Outdoor Pathways: Aluminum profiles keep LED strips safe from water and dust, making them last longer.

Gardens: They add nice lighting that highlights garden features.

Building Facades: These profiles provide useful lighting and make buildings look better.

In both new and old buildings, you can pick from different types of aluminum profiles. These include surface-mounted, recessed-mounted, and corner profiles. Each type meets different installation needs, making aluminum a flexible choice for your projects.

Applications for Plastic Profiles

Plastic profiles work well in certain situations where being flexible and cheap is important. You might think about using plastic profiles for:

Indoor Spaces: They are good for places needing soft lighting, like kids’ rooms or themed areas.

Temporary Installations: Their light weight makes them easy to put up and take down.

Creative Designs: Plastic profiles can be shaped into fun forms, allowing for cool lighting ideas.

While plastic profiles may not be as strong as aluminum, they can still work well in easier environments. Their ability to spread light creates a cozy feel, making them great for decorative uses.

Installation Tips

Installing Aluminum Profiles

When you put in aluminum profiles for your LED strips, follow these easy steps to make sure it goes well:

Prepare Your Tools: Get the tools you need. This includes LED strip lights, aluminum profiles, mounting clips or brackets, a power supply, a diffuser, adhesive backing or screws, a hacksaw, measuring tape, and a screwdriver or drill.

Clean the Surface: Make sure the surface is clean and dry. This is very important for sticking well.

Measure and Cut: Measure how long you need for your installation. Use a hacksaw to cut the aluminum profile correctly.

Secure the Profile: Use mounting clips or brackets to attach the profile to the surface. Press down hard after pasting to stop the strip from falling off.

Check for Alignment: Use leveling tools to make sure the aluminum joints are straight. This stops any uneven look in your setup.

Protect Wires: Plan your wiring carefully to keep wires hidden. A good routing plan will help you keep everything neat.

Here are some common problems you might face during installation:

Challenge | Description |

|---|---|

Strip falling off | Make sure the aluminum surface is clean, use good LED strips, and press down hard after pasting. |

Uneven aluminum joints | This happens from cutting mistakes; you need to measure well and use leveling tools to fix it. |

Exposed wires | This happens from poor planning and not enough wire protection; you need a good routing plan and protection. |

Installing Plastic Profiles

Putting in plastic profiles can be easy if you follow these tips:

Choose the Right Fasteners: Pick the right fasteners for your needs. Here’s a quick guide:

Fastener Type | Description | Best For | Advantages | Disadvantages |

|---|---|---|---|---|

Mounting Clips/Brackets | Clips that hold the LED strip tightly by screwing into the surface. | Long runs, vertical surfaces, overhead applications. | Very secure, spreads weight, looks nice. | Needs drilling holes. |

Zip Ties / Cable Ties | Wraps around the strip to hold it to non-flat surfaces. | Furniture legs, metal shelves. | Cheap, easy to use, adjustable. | Only for wrap-around situations. |

Aluminum Channels | Extrusions that hold the LED strip, giving support. | High-end installations. | Strong, good for sticking, cools down heat. | More expensive, needs installation. |

Consider Channel Mounting: Channel mounting has many benefits:

Protects LED strips from dust and dirt.

Gives a smooth lighting effect.

Hides the LED strips for a clean look.

But remember, channel mounting can cost more and take more time.

By following these tips, you can get a professional look for both aluminum and plastic profiles. This way, your LED strips will look great and work well.

In conclusion, aluminum and plastic profiles for LED strips each have their own benefits.

Aluminum profiles give:

More strength and protection.

Better heat removal, which helps LEDs last longer.

Plastic profiles offer:

A lighter and cheaper choice.

Flexibility for fun designs but do not manage heat well.

When picking a profile, think about what you need. For bright lighting or detailed work, aluminum is best. For decorative or soft lighting, plastic can work.

Type of LED | Best Uses |

|---|---|

SMD LEDs | Detailed Lighting, Bright Lighting Needs |

LED软灯带 | Decorative Lighting, Soft Lighting, Building Lighting |

In the end, focus on long-term use and care when deciding. Aluminum profiles usually mean fewer replacements and lower maintenance costs, making them a smart choice for lasting quality.

FAQ

What are the main benefits of using aluminum profiles for LED strips?

Aluminum profiles are very strong, cool down well, and look nice. They keep LED strips safe from outside elements. This helps them last longer and work better.

Can I use plastic profiles outdoors?

Plastic profiles are usually not good for outdoor use. They can break down when exposed to UV light. They also may not handle bad weather as well as aluminum profiles.

How do I choose between aluminum and plastic profiles?

Think about what your project needs. If you want something strong and good at cooling, pick aluminum. If you need something cheaper and flexible, plastic profiles might work.

Are there any maintenance requirements for these profiles?

Both aluminum and plastic profiles need little maintenance. Check for dust build-up and clean them if needed. Make sure the LED strips stay securely attached.

Can I paint or customize aluminum profiles?

Yes, you can paint or customize aluminum profiles. Use paints made for metal surfaces to keep the paint sticking well. This helps you match your decor easily.

See Also

Comparing Flexible Versus Rigid LED Strip Options

In-Depth Comparison of SMD 2835, 5050, and 3528 Strips

Evaluating High-Brightness LED Strips for Various Uses