LED strip lights are flexible and easy to customise. They are great for creative lighting ideas. But, you should only cut them at marked spots. These spots have copper pads or scissor symbols. Cutting in other places can break the strip and stop electricity. If you are doing a DIY project or changing the length, be careful. Use proper tools and follow the marks to keep the strip working and safe.

Key Takeaways

Cut LED strip lights only at marked spots with copper pads or scissor signs to avoid breaking the circuit.

Use sharp scissors or a craft knife for neat cuts. This helps the LEDs work properly after cutting.

Join cut LED strips using clip-on connectors for easy fixes or soldering for a stronger hold.

Unplug the LED strip before cutting to stay safe and avoid shocks.

Plan your LED strip design well to avoid extra cuts and make it fit perfectly in your project.

Where to Cut LED Strip Lights

Finding Safe Cutting Spots

To cut LED strip lights, find the safe cutting spots. These are marked with copper pads or scissor symbols. Copper pads connect the circuit, keeping the LEDs working after cutting. Check the strip’s surface or back for these markers. Some strips also have dotted lines near the copper pads to guide you.

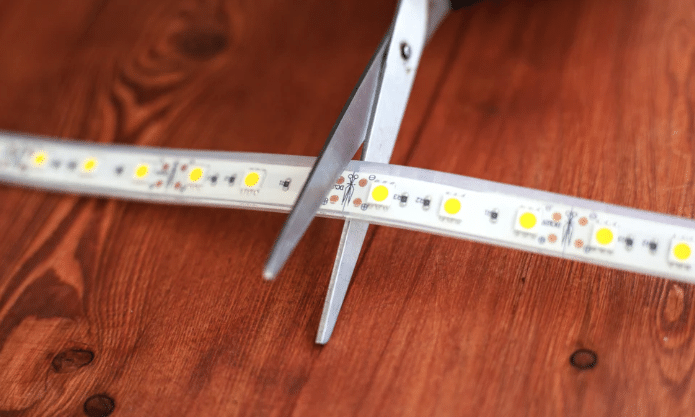

Before cutting, unplug the LED strip to stay safe from electricity. Use sharp scissors or a craft knife for a neat cut on the marked line. A clean cut keeps the circuit working and the LEDs lighting up. Do not cut through diodes or connectors, as this can break the strip.

Why Cutting at the Right Spots Matters

Cutting LED strips at the right spots is very important. Copper pads show where a circuit ends, so cutting elsewhere can break it. This might stop some LEDs from lighting or damage the whole strip.

A neat cut on the marked line avoids harming the parts. It also lets you reconnect the cut pieces later if needed. Using sharp scissors helps you cut cleanly without damaging the copper pads or LEDs.

How LED Strip Circuits Work

LED strips have small circuits powering groups of LEDs, often three. Copper pads mark where these circuits end, making them the only safe cutting spots. Cutting here keeps the electricity flowing properly.

If you want to reconnect cut pieces, think about the circuit design. Use solderless connectors or soldering to join the copper pads. This keeps the connection strong and the LEDs working. Always check your power supply when joining strips to avoid overloading it.

How to Cut LED Strip Lights

Tools Needed to Cut LED Strip Lights

To cut led strip lights effectively, you need the right tools. Sharp scissors or a craft knife works best for clean cuts. A tape measure helps you measure the exact length of the strip. These tools ensure precision and prevent damage to the copper pads. Always use sharp tools to avoid frayed edges, which can disrupt the circuit.

Step-by-Step Guide to Cut LED Strip Lights

Follow these steps to cut led strip lights accurately:

Measure the area where you plan to install the strip. Use a tape measure for precise dimensions.

Locate the nearest copper pad on the led strip. These pads mark the safe cutting points.

Place the strip on a flat surface. This ensures stability while cutting.

Use sharp scissors or a craft knife to cut along the marked line. Apply steady pressure for a clean cut.

Test the connection by reconnecting the sections with an LED strip connector.

Avoid cutting between the copper pads. If you accidentally cut in the wrong place, you may need to solder the circuit, which requires experience.

Safety Tips for Cutting LED Strip Lights

Safety is crucial when cutting apart led strips. Always unplug the strip before cutting to avoid electrical hazards. Ensure the voltage of your power supply matches the strip’s specifications. Use proper connectors to secure the connections and prevent exposed wires. Install the strips in well-ventilated areas to avoid overheating. For outdoor or bathroom use, choose waterproof or water-resistant strips.

Tip: Keep the strips away from water sources and flammable materials to ensure safety and longevity.

By following these steps and safety measures, you can confidently cut led strip lights without damaging them.

How to Reconnect LED Strip Lights

Using Connectors to Reconnect LED Strip Lights

Connectors are an easy way to join cut LED strips. They are simple to use and great for beginners. Follow these steps to reconnect your LED strip:

Match the connector with the positive and negative ends of the strip.

Place the cut ends into the connector slots carefully.

Push the locking tab down to secure the connection.

Make sure the copper pads line up with the connector clamps. If they don’t, the LEDs might not work properly. Use tape or clips to keep the strips steady and in place.

Type of Connector | Description | Tools Needed |

|---|---|---|

Solderless Connectors | Easy to use, no special tools required. | None |

Soldering Connections | Needs soldering iron, good for a lasting connection. | Soldering iron |

Connectors make reconnecting LED strips fast and reliable.

Soldering LED Strip Lights After Cutting

Soldering is a stronger way to reconnect LED strips. You will need some tools and basic skills. To solder the strips:

Heat the soldering iron and add a little solder to the copper pads.

Attach the red wire to the copper pad with a plus sign.

Attach the black wire to the copper pad with a minus sign.

Be careful to avoid extra solder touching other parts. This can cause short circuits. Soldering gives a solid connection, perfect for long-term use.

Tip: Practise soldering on spare wires first to improve your skills.

Testing and Troubleshooting Reconnected LED Strip Lights

After reconnecting, test the LED strip to check if it works. First, ensure the power supply matches the strip’s voltage. Look for any damage or wrong connections.

If the LEDs don’t light up, use a multimeter to check the voltage. Check for short circuits caused by extra solder or exposed wires. Also, test the remote and controller settings to fix any setup problems.

Note: Moisture or extreme heat can affect LED strips. Make sure the area is suitable for installation.

By following these steps, you can fix most problems with reconnecting LED strips.

Troubleshooting Problems After Cutting LED Strip Lights

LED Strip Not Lighting After Cutting

If your LED strip stops working, check the power supply first. Make sure it matches the strip’s voltage rating. Wrong voltage can stop the LEDs from lighting. Look for loose or disconnected wires that might block electricity flow. Check for damage like broken or cut LEDs, which can cause problems.

Use a multimeter to check voltage along the strip. Test the copper pads at different points. If voltage drops far from the power source, the strip may lack power. This could mean the power supply is weak or the strip is too long.

Tip: Always check the positive and negative ends are connected correctly. Wrong polarity can stop the strip from working.

Flickering or Uneven Light in LED Strip

Flickering or uneven light often happens because of voltage drop. Longer strips have more resistance, reducing power at the end.

Voltage drop in longer LED strips happens due to resistance. More resistance means less power reaches the strip’s end, causing flickering or dim lights.

Other reasons include a bad power supply, damaged LEDs, or loose connections. Check the power supply for steady voltage. Inspect the strip for broken LEDs or poor connections. Replace any faulty parts to fix the lighting.

Issues Reconnecting Cut LED Strip Lights

Reconnecting cut LED strips can sometimes cause problems. If LEDs don’t light up, check if copper pads align with connector clamps. Misaligned pads can break the circuit.

Use a multimeter to find short circuits. These often happen near the cut-line. If you find one, remove accessories and inspect the strip. Cutting off 1-2 inches of the strip may fix it.

Check all connections visually. Ensure wires are secure and separate.

Use a multimeter to find hidden short circuits.

Remove accessories and retest if a short circuit is found.

Note: Soldering mistakes can also cause issues. Avoid letting extra solder touch other parts, as this can create short circuits.

By following these tips, you can solve most LED strip problems after cutting.

Tips for Cutting and Reconnecting LED Strip Lights Successfully

Plan Your LED Strip Layout Before Cutting

Planning ahead makes your LED strip project easier. Measure the area where you’ll place the strip. Think about corners, obstacles, and the total length needed. This helps you avoid extra cuts and ensures a perfect fit.

Make a clear plan for your project. List all materials like connectors and power supplies. Check you have enough connectors to join sections. Don’t exceed the power source’s recommended strip limit.

Tip: Measure a bit longer than needed. This allows small adjustments during setup.

Planning also helps you imagine how your LED strip will look. Use design software or draw your idea on paper. This way, you can get the lighting effect you want and avoid errors.

Use Good Tools and Accessories for LED Strips

Good tools and accessories make your LED strips last longer. Clean the strip often to remove dust, which can dim the lights. Make sure there’s good airflow to stop overheating.

Here are important things to check when picking LED strips:

Quality Factor | Description |

|---|---|

Circuitboard Strength | Strong circuitboards with 2-4 oz copper handle power better and prevent voltage drop. |

LED Quality | Good LEDs give steady light. Fewer, poor-quality LEDs can fail quickly. |

Strip Surface | High-quality strips have reflective coatings for brighter light. Cheaper ones may not. |

Note: Spending more on good tools and parts keeps your LED strips working well for years.

Also, use sharp scissors or a craft knife for neat cuts. Strong connectors and soldering tools make secure connections. These tools make the job easier and improve your LED strip’s durability.

Cutting and joining LED strips is easy if done right. Always cut only at copper pads to keep the circuit working. Use sharp tools for neat cuts, which are very important.

You can reconnect strips using connectors or by soldering. Both need care to avoid electrical problems. After reconnecting, test to make sure it works properly.

Important Tip | Explanation |

|---|---|

Where to Cut | Cut only at copper pads to avoid damaging the circuit. |

How to Cut | Use sharp scissors or a craft knife for a clean cut. |

Ways to Reconnect | Use connectors or soldering, each needing specific tools and care. |

Plan well and use good tools to adjust your LED strips. This method helps you create a safe and lasting lighting project.

FAQ

Can you cut LED strip lights anywhere?

No, you must cut LED strip lights at marked spots. These spots usually have copper pads or scissor symbols. Cutting in other places can break the circuit. This will stop the LEDs from working. Always look for these markers before cutting.

What tools do you need to cut LED strip lights?

You need sharp scissors or a craft knife for neat cuts. A tape measure helps you measure the strip correctly. For reconnecting, use connectors or a soldering iron. The right tools help you avoid damaging the strip.

How do you reconnect LED strips after cutting?

Reconnect LED strips with solderless connectors or by soldering wires. Match the copper pads with the connector clamps or solder them. After reconnecting, test the strip to check if it works.

Tip: Use connectors for quick repairs and soldering for stronger connections.

Why is my LED strip flickering after cutting?

Flickering happens because of voltage drop, loose wires, or weak power. Check the power supply and make sure all wires are tight. Look for damaged LEDs or misaligned copper pads. Fixing these problems usually stops flickering.

Can you use LED strips outdoors after cutting?

Yes, but only if the LED strips are waterproof or water-resistant. Seal the cut ends with silicone or waterproof connectors. This keeps moisture from ruining the circuit. Always check the product details before using them outside.

Note: Protect outdoor LED strips from bad weather to make them last longer.

See Also

Techniques For Cutting COB LED Strip Lights Precisely

A Comprehensive Guide To Installing LED Strip Lights 2025

Effective Methods For Installing RGB LED Strip Lights